We produce fresh spruce lumber. Using the latest technology, our experienced employees fulfil the wishes and orders of our customers.

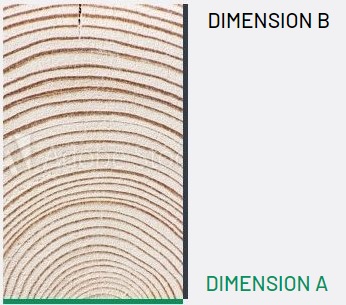

Our technologies at the highest European level achieve the following maximum possible dimensions of timber:

DIMENSION A: 150 mm

DIMENSION B: 300 mm

Wood waste generated when the roundwood is recieved to our mill. It is a mixture of bark and wooden parts from the reduction of tree butts. The content of inert material is also common. It is suitable for further sorting and grinding, mulching, composting, burning for heat, etc.

The bark is made out by debarking logs before the production of lumber. The bark is not further modified and is therefore suitable for further sorting, grinding or mulching.

Sawdust is formed during the cutting of raw, coniferous, debarked roundwood. It is suitable for the production of pellets, briquettes, board materials, WPC elements, bricks. It can also be used for burning or animal bedding.

Wood chips are produced as a by-product of wood processing or aimed grinding of wood parts. 100 % of wood chips is taken from us by Mondi Štětí a.s.

The issue of sustainability is an important aspect of natural and renewable raw materials such as wood. The owners and management of LABE WOOD s.r.o. are fully aware of the importance of sustainable and ecologically sound forest industry, therefore they undertake to apply and maintain the requirements of the consumer chain of forest products under the PEFC and FSC®.

The company holds certificates according to both standards.

We are able to offer FSC® or PEFC certified products on request.

In addition to the fact that we use only wood from sustainably managed forest areas, we process residues from wood manufacturing in an ecological way, such as wood chips, sawdust and bark. The chips are completely used for paper production in the subsidiary Mondi Štětí a.s. and sawdust and bark are used to produce environmentally friendly fuels or burned directly to produce green electricity and heat.